Food & Beverage

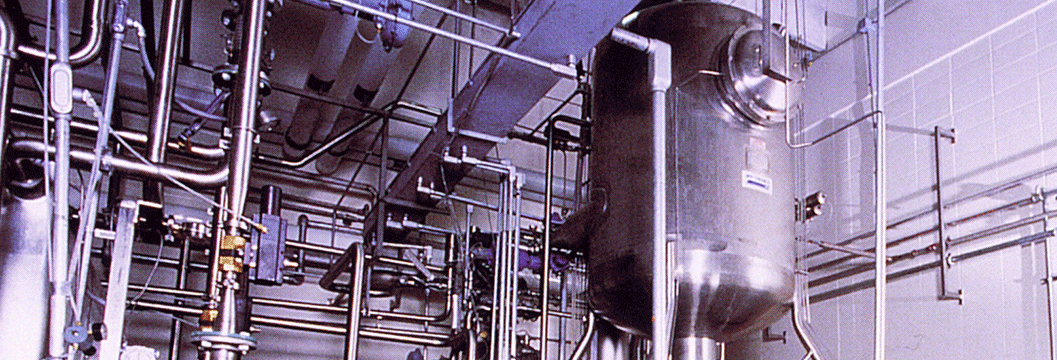

The food and beverage industry requires an industrial contractor who understands the critical role in the execution required for a successful project. Maintaining product purity is essential for all installations, modifications, service, repairs, and maintenance work. Equally important is the ability to provide prompt and effective emergency response for all process cooling, and cold storage emergencies. In 1986 Scheck Industries was awarded its first food project and since then has been a recognized leader in piping systems that satisfy the special requirements of ultra-clean projects and industrial refrigeration applications. We can also provide ongoing maintenance with our large, national workforce of skilled craftsmen and project managers who have countless years of experience in this field. You will find that our employees take great pride in the quality of their work and are the main reason we enjoy long-term relationships with some of the most prominent names in the industry. Our capabilities include:

- 3A Sanitary qualifications

- Stainless steel welding procedures

- Orbital welding for high purity systems

- Boiler installation and repair

- Humidification and dehumidification systems

- Waste treatment plant

- Pneumatic conveying of product

- Bag in box packaging

- Chemical clean in place

- Conveying systems – box

- FDA traceability

- Dust capture system

- Product cleanliness techniques

- Dense phase material transport

- Vitamin application

- Various coating systems (frosting/sugar)

- Traveling grate ovens

- Batch cooking process cooling

- Cold storage warehousing

- Thermal storage

- Industrial bakeries

- Batch mixing of product

- 24 hour emergency response

Partial List of Clients

- Best Foods

- Cargill

- Cerestar USA Inc.

- Häagen-Dazs

- Ingredion (f/k/a Corn Products International)

- Kellogg’s

- Kraft Foods Group, Inc.

- Nabisco

- Nestle USA

- Pillsbury

- Plochman, Inc.

What our Clients are Saying

- Your organization’s involvement as the General Contractor made a significant impact on the success of the project.

- All of this has been possible because of you. Your support and involvement in what has been done on the project produced this success and you should be proud.

- There is no one we know who wouldn’t happily give Scheck Mechanical Corporation a Grade ‘A’ on all levels.

- Rich, your people are uniquely qualified and continuously work together with us as a real team. They completed repairs very professionally and on a timely basis. Please let your team know that their professionalism and expertise is greatly appreciated. Keep up the good work.

- As the project progressed, we were no longer Plochman and Scheck, but a team with one specific goal.

- We rely heavily on the talent and professionalism of Scheck to help us accomplish our goals. They continue to do an excellent job.

- It’s absolutely great to work with people that know their job as well as these gentlemen do.